Parallel Strand Lumber (PSL) Means and Methods

An Analysis of Weyerhaeuser's 5 1/4" x 16" 2.0E Parallam® Plus Parallel-Strand Lumber (PSL) 2.0E on Townhome Back Deck

INTRODUCTION

In February 2021, after doing some research on my deck beam, I noticed that something wasn't quite right. In addition, I noticed neighbors having repair work performed on their beam, which raised some questions and concerns. I enjoy construction and learning new things related to construction, so I made the decision to dig a little deeper. First, I took a look at the structural construction drawings (available to the public via Henrico County Building Inspections), which were labeled with a 5 1/4" x 16" Parallel-strand Lumber (PSL) 2.0E Wolmanized (SL-2). Below is a plan view of the back deck from the Structural Construction Drawings, Sheet S-114 as well as the deck beam to post connection detail from Sheet S-303. The beam is highlighted in yellow, spanning approximately 20 feet.

Figure 1. Screenshot from structural drawing for my townhome obtained from the Henrico County Building Inspection Department. The plan view of the back deck of the townhome is 20 ' x 12'-5 1/2". It is drawn from a horizontal plane looking down from above.

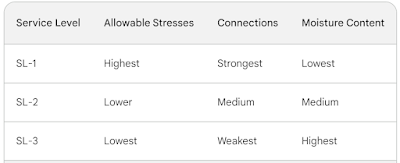

Figure 2. Deck Beam to Post Connection, Sheet S-303. The bearing length is approximately 6 inches. This is where the beam comes into contact with the Wood Post (6"x6" member per the Post Schedule).Note: SL-2 means it was designed for Service Level 2, or wet use with an allowable moisture content > 16% and <= 28%. Service Level 3 (SL-3) is Weyerhaeuser's designation for "Saturated Use with an allowable moisture content >28% that is exposed to continuous wet conditions. Per the construction drawings, the beam was not designed for Service Level 3, exposure to continuous wet conditions. More information on Service Levels at the bottom of this blog.

The beam is an Engineered Wood Product (EWP), manufactured by Weyerhaeuser. Parallel Strand Lumber allows for the support of heavy loads and longer spans. After digging into old photos that I took during the construction of the home, I verified that it was, in fact, a Weyerhaeuser Parallel-strand Lumber (PSL) 2.0E Wolmanized beam, as labeled on the member in the photo (below) and the construction drawings.

Figure 4. Picture of deck beam taken on September 28, 2021, after removing wrapping and before repair. The beam is labeled as complying with ICCES ESR 1387 and CCMC 11161-R and meeting a minimum stiffness of 2.0E, constructed with Eastern species (Southern Pine and/or Yellow Poplar). According to the markings, the beam was manufactured on November 30, 2017, at 13:37 and was most likely manufactured at the Buckhannon, West Virginia facility.

Figure 4. Picture of deck beam taken on September 28, 2021, after removing wrapping and before repair. The beam is labeled as complying with ICCES ESR 1387 and CCMC 11161-R and meeting a minimum stiffness of 2.0E, constructed with Eastern species (Southern Pine and/or Yellow Poplar). According to the markings, the beam was manufactured on November 30, 2017, at 13:37 and was most likely manufactured at the Buckhannon, West Virginia facility.

Also noted on Sheet S-001 by the registered design professional, are the Design Loads and Minimum Allowable Design Value; (100% load duration):

Figure 5. Design Loads on Construction Drawings, Sheet S-001.

WHAT DOES THE MANUFACTURER SAY?

- I contacted Weyerhaeuser and presented my questions/issues and received a reply with the following (Weyerhaeuser was not involved in the design or engineering of the home):

- The details presented suggest that the cladding did not follow recommendations as stated in TJ-7102. Cladding should be installed with furring strips and allow drainage to prevent moisture entrapment (as shown on page 10). Without this drainage, the beam will trap moisture, which may lead to performance issues.

- The issue is primarily structural since the beam now needs to be designed for wet use – it cannot be dried.

- Weyerhaeuser provides a Specifier's Guide (#TJ-7102) at the following link, which provides specifications and warranty information.

- Cladding Information Parallam® Plus PSL is suitable for exposed conditions with wet-dry moisture cycles. However, it may be desirable for aesthetic reasons to wrap the product in a decorative cladding. As with all treated wood products, avoid applications that can trap moisture. If decorative cladding is used, the following considerations are critical for Parallam® Plus PSL to perform satisfactorily:

- The designer, builder, and owner must share responsibility for ensuring that the assembly is designed, installed, and maintained in a way that will prevent water from entering and being trapped.

- If the prevention of water intrusion over the life of the structure cannot be assured, then cladding must be designed and installed in a manner that allows adequate drainage and sufficient air-flow to facilitate drying. Suggested beam and column details are shown at right.

- Water runoff from repeated wetting may transfer residue, such as excess preservative, natural wood extractives, and dirt, which can result in discoloration of architecturally sensitive surrounding construction. Where this is a concern, detailing that limits the potential for repeated water exposure should be used.

- Metal cladding materials should not be used, as the preservative treatment can react with the metal and lead to corrosion of the cladding and fasteners.

- All fasteners, furring strips, and other materials used in the cladding assembly must be corrosion-resistant, treated, or otherwise resistant to decay.

- Vented cladding, such as a soffit or drilled cladding material, should be used to allow proper drainage. Routine maintenance is also required to ensure that vent holes remain open and free of debris.

- For column bases with ground contact, maintain a 3" (minimum) gap between cladding and finish grade for drainage. For bases with patio or deck surface contact, maintain a 1" (minimum) gap between cladding and surface.

- Weyerhaeuser goes on to explicitly state the following along with an illustration of cladding on beams:

WHAT DOES THE BUILDING CODE SAY?

Virginia Uniform Statewide Building Code. Virginia Code 13VAC5-63-120. Section 112 Workmanship, materials and equipment, D. Section 112.3.1 Conditions of listings (https://law.lis.virginia.gov/admincode/title13/agency5/chapter63/section120/), states:

Where conflicts between this code and conditions of the listing or the manufacturer's installation instructions occur, the provisions of this code shall apply.

Exception: Where a code provision is less restrictive than the conditions of the listing ofthe equipment or appliance or the manufacturer's installation instructions, theconditions of the listing and the manufacturer's installation instructions shall apply.

THE WARRANTY

- Damage to Product resulting from fires, floods, natural disaster or any other cause beyond Weyerhaeuser’s control.

- Damage to Product resulting from misuse, improper product applications or installation of the Product, or noncompliance with the installation instructions, applicable building code or generally accepted construction practices.

- Defects in the structure due to construction, installation or manufactured sub-assembly.

- Any alterations to the Product after the original installation.

THE OUTCOME

More on Service Levels

- The allowable stresses for the lumber are lower for SL-3 than for SL-1. This means that the lumber can support less weight in SL-3 conditions.

- The connections between pieces of lumber must be designed differently for different service levels. For example, withdrawal connections (where a piece of lumber is pulled out of another piece of lumber) must be stronger for SL-3 than for SL-1.

- The moisture content of the lumber must be controlled in order to maintain the desired service level. For example, if the lumber is exposed to rain, it may need to be dried out before it can be used in SL-1 conditions.

Forte Web Report - Reactions, Shear, Moment, Deflection

I created code in Python to calculate the deflection, which differs by 0.06564 inches or 9% more than ForteWeb's results. See below for the code and results:

REFERENCES:

- Virginia Uniform Statewide Building Code » Part I. Construction » 13VAC5-63-120. Section 112 Workmanship, materials and equipment.

- Paralam Plus PSL Limited 30-Year Warranty - TJ-7101

- Specifier's Guide for Parallam Plus PSL - TJ-7102

- Moisture Effects on Weyerhaeuser Engineered Wood Products and Oriented Strand Board - TB-112

- Construction Drawings obtained from Henrico County Department of Building Inspections via Freedom of Information Act (FOIA).

- ICC-ES Report No. ESR-1387

- ForteWEB

- Python Software Foundation. Python programming language. Python Software Foundation, 2023. https://www.python.org/

.jpg)

No comments:

Post a Comment